Marine DNV certified MIT device with Glass-Glass PCT aiming for Industry 4.0

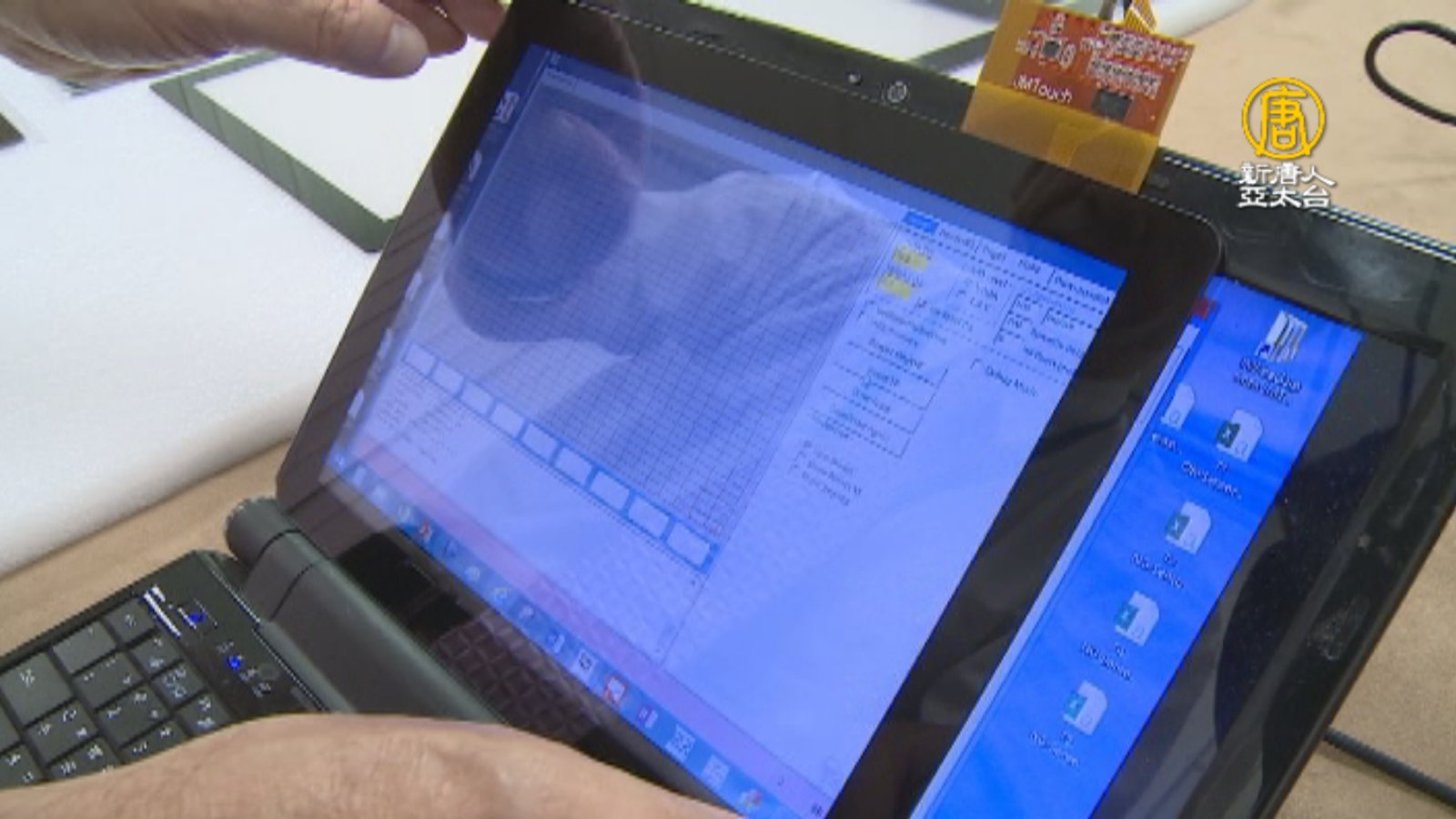

【新唐人亞太台 2017 年 06 月 26 日訊】Dr. Jeng-Maw Chiou, President of a high-tech cooperation, depicts “The cruise members may wear leather or working gloves to manipulate the HMI device on ship during winter time like this way.”

While operating with either single or five fingers at the same time, it always feeds back with smooth performance. Its secret is originated from this piece of glass-glass type Projected Capacitive Touch (GG PCT), found spread applied in the fields of consuming IOT, such as mobile phones, wearing devices, etc. Taiwanese manufacturers were further investing in industrial computer-related applications, including marine applications, and furthermore passing through the most stringent DNV certification of IEC60945.

Dr. Jeng-Maw Chiou, President of a high-tech cooperation, depicts “Inside the industry, we all know it is a super difficult one. It must meet strict standards in some areas, including humidity, temperature, vibration, electromagnetic interference, etc. It is normally required that the marine system integrators can only adopt those devices with such certifications.”

By comparing with those generally used Glass-Film-Film Type Projected Capacitive Touch (GFF PCT), glass-glass type Projected Capacitive Touch (GG PCT) owns transparency up to 90%. The assembled PCT can be further end up to 95%, or even higher, by adopting “full bonding process” with LCD panel. In terms of weather resistance, it can be operated at temperatures between -40 and 85oC and without yellowish issues after long-term use. We can offer customization services for GG PCT both in wide range of sizes, from 5 to 32”, and without any limit in aspect ratios, other than popular 4:3, 16:9, etc. Furthermore, our production technology is quite easily to serve for small amount needs.

Dr. Jeng-Maw Chiou, President of a high-tech cooperation, depicts “We reduce glass sensor manufacturing processes from 30 to 5 steps. Furthermore, simplify the 5- manufacturing processes to not using chemicals, not generating waste chemicals and waste water. Of course, less electric power is used. In short, our manufacturing processes are very green eventually.”

The team adopts some special optical technology, instead of normally used photo-etching or screen printing technologies, which significantly shorten the processes to achieve environmental protection and energy conservation. Enabling the team to such idea is mainly due to the experiencing the Asian financial turmoil and enduring the competition from China. It turns out a decision to expand the business of making multi-touch projected capacitive touch into well-developed Taiwan IPC industry.

Dr. Jeng-Maw Chiou, President of a high-tech cooperation, depicts “Other than in consumer industry, many companies in this industry are working with partnership, no matter upstream or downstream ones. It is really much more suitable for Taiwanese business players to gradually migrate into these kinds of niche markets.”

According to market analysis data, the shipments of multi-touch PCT could reach 27 million sets in 2016, with future total revenue possibly up to 40~50 Billion NTD. Taiwanese teams are aiming Industry 4.0, including aviation, marine, medical and automotive applications, to enable MIT products to market internationally.

Information

-----------------------------

JMTouch

-----------------------------

相關新聞

-

MIT GG PCT 獲DNV航海認證朝4.0發展

2017-05-24 10:22:02不僅智慧手機用手指滑動操作,工業電腦人機介面,也需要多點觸控模組,其中,「玻璃-玻璃」多點投射電容觸控的透光率較高,加上耐候性佳,不少業者投入研發,有台灣團隊應用在工業4.0,並拿下最嚴苛的DNV航海認證,為MIT產品,行銷國際。

-

MIT GG PCT 獲DNV航海認證往工業4.0發展

2017-05-28 06:49:37不僅智慧手機用手指滑動操作,工業電腦,人機介面,也需要多點觸控模組,其中,「玻璃-玻璃」多點投射電容觸控的透光率較高,加上耐候性佳,不少業者投入研發,有台灣團隊,應用在工業4.0,並拿下最嚴苛的DNV航海認證,為MIT產品,行銷國際。

-

The Trade War makes Taiwan Business Transform into automated R&D of agricultural machinery belts

2019-10-16 22:02:33Rubber products are also on the tariff list of the US-China trade war. Chih-Sung Chang, the Chairman of one of the top 3 rubber drive belt manufacturers of Taiwan mentioned that there is an obvious growth of domestic orders and overseas inquiries, which p

-

外商搶攻檢測商機 新竹車聯網實驗室啟用

2017-01-12 21:00:47看好車聯網商機,國際知名的檢測認證公司,在台灣新竹設立一座車聯網實驗室,今 (12) 日正式啟用。不只為汽車供應商和零組件製造商,提供測試和認證。就連IT產業、電信業以及電子醫療等等,都可以在這裡完成檢測。

-

語音管家「Echo」熱賣 鴻海獨家進補

2016-09-26 12:51:40亞馬遜股價近期大漲,總市值飆升到3820億美元,僅次於蘋果、Google和微軟,居第四位。其中一大原因,就是旗下語音智慧管家產品Echo熱賣,而這項產品由國內大廠鴻海代工,銷量明年上看千萬台,可望為營收帶來挹注。

-

緯創拚AI加碼投資高雄 透露與微軟新進度

2018-01-05 20:39:51迎接AI時代來臨,科技大廠緯創資通,今天(5日)宣布加碼投資高雄,成立第二辦公室,將以人工智慧和物聯網等軟體產品研發為主,預計3年內,招募200位軟體研發工程師,緯創資通執行長黃柏漙也透露,與微軟合作的最新進度。

-

路燈成為物聯網載具 智慧城市第一哩路

2018-09-01 21:00:42再來看到,路燈升級成為物聯網載具,結合5基地台、多樣化的感測器,進行環境、交通、防災監測、社區照顧等,蒐集數據進行智慧城市管理,成為實踐智慧城市的第一哩路。昨天(31日),桃園舉辦的智慧路燈論壇,展示台灣產業發展及試驗的結果,藉由路燈升級,搶佔物聯網及AI先機。

-

智慧城鄉交流 運用智慧交通生活更便利

2018-02-26 22:04:17歡迎收看今天的好樣Formosa。首先帶您看到,行政院長賴清德於去年9月視察亞洲.矽谷執行中心桃園總部時,特別指示籌辦各城市間的智慧城鄉建設研討會,讓各縣市可以互相切磋、擷取優點。本週 亞洲.矽谷第一站在桃園展開,智慧城市建設經驗交流巡迴分享會,將階段性成果分享給各縣市與企業界了解。

-

日本軟銀再出招!IoT平台招手外企

2016-10-14 21:42:38今天的日本傳真我們要帶您看到,軟體銀行公司佈局物聯網產業,不僅在7月收購英國晶片設計公司ARM,也早早成立IoT消費服務平台。今天,軟銀在新品記者會中,除了日本本地企業外,也能看到許多外國企業的展示。請看我們東京記者的報導。

-

物聯網趨勢到來 國際大廠看台灣!

2015-11-19 21:13:01好,那在今天的ARM科技論壇中,國際大廠也爭相參與,對於,即將在數年內迎來的物聯網趨勢,業者又是怎麼看得呢?

-

專訪台灣微軟二當家!看好物聯網前景

2016-08-16 21:26:11微軟從2014年啟動轉型計畫,包括推出線上服務,還有旗下雲端物聯網產品;七月份,台灣微軟行銷和營運事業,由來自日本的磯貝直之 掌舵,上任滿一個月,接受本台專訪,這位科技行銷專家,他認為,在全球物聯網趨勢下,台灣是最佳發展國家之一。

-

數位經濟浪潮 童子賢:IoT是台灣下個機會

2017-12-20 21:21:53資通訊產業對台灣經濟扮演重要角色,北市電腦公會理事長童子賢,今天出席活動時表示,數位商機無所不在,展望未來數位經濟浪潮,IoT物聯網應用,將可能是台灣中小企業,百花齊放的機會。

-

語音管家「Echo」熱賣 鴻海代工受惠

2016-10-02 16:03:17再來看到,亞馬遜股價近期大漲,總市值飆升到3820億美元,僅次於蘋果、Google和微軟,居第四位。其中一大原因,就是旗下語音智慧管家產品Echo熱賣,而這項產品,是由國內大廠鴻海代工,銷量明年上看千萬台,可望為營收,帶來挹注。

-

看好IOT未來 遠傳啟動智慧家庭計劃

2015-06-18 13:10:23財經訊息來看到,遠傳電信18日舉行股東會,全面改選11席董事及獨立董事,特別的是,遠傳董事長獨子徐國安正式進入遠傳董事會,為未來接班做準備,下半年徐旭東表示,將進軍智慧家庭生活領域,看好IOT未來發展。

-

省電節源力驚人 全台首座智慧漁港國際獲獎

2019-09-03 21:15:01基隆市發展智慧城市已經逐漸展現亮麗成果,上個月28日還剛在泰國曼谷獲得亞太資訊服務業組織(ASOCIO)的「2019智慧城市獎」,其中,基隆長潭智慧漁港更是其中的獲獎關鍵,智慧管理除了大幅節電外,更是減少了所需的人力成本。

-

亞洲矽谷獲回應!經濟部結盟高通力推IOT

2016-11-07 13:40:09經濟部今天與美國高通 共同簽署合作備忘錄,雙方將共同合作加速推動台灣建立4G+╱5G行動網路技術與物聯網產業鏈。

-

企業搶進佈局物聯網 Google將推Brillo

2015-05-27 07:09:26物聯網是最近科技界的關鍵字,也有人將它稱為第四次工業革命。在2014年,全球科技業有關物聯網的相關併購,就達到了140億美元,各大企業正積極佈局。

-

亞馬遜首度參展!Computex展區創記錄

2018-06-05 21:44:002018台北國際電腦展,明天即將登場,今年聚焦人工智慧、物聯網、5G、以及區塊鏈領域,新創展區的規模破紀錄。電商龍頭亞馬遜,今年更是首次來台參展。

-

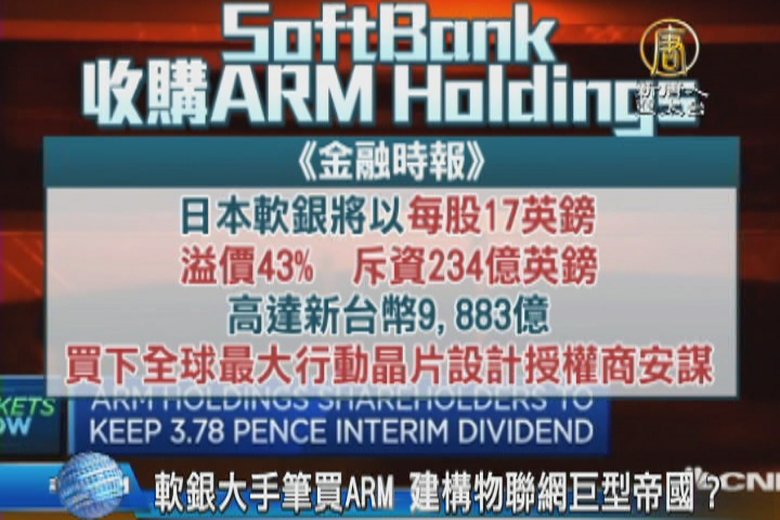

軟銀大手筆買ARM 建構物聯網巨型帝國?

2016-07-18 20:40:12日本 SoftBank 確定以 234 億英鎊(約台幣 9,897 億元)的價格,收購英國 IC 智財授權廠商安謀(ARM),成為歐洲史上最大的科技業併購案。

-

IOT新創家Zach來台 看好台軟硬整合實力

2016-01-19 20:49:26被譽為十大創新物聯企業之一Particle,創辦人今天受邀來台,他認為,物聯網趨勢台灣不容錯過,更應該積極發揮台灣軟硬整合的優勢,建議政府扮演協助角色,讓產業更加茁壯。